Hydrocooling is a fast and efficient way of cooling water-tolerant fruits and vegetables after harvest by pre-chilling them in cold water to preserve their freshness and prolong shelf life. When produce is harvested from the fields, the high temperatures and humidity they retain threaten their quality. For this reason, it is beneficial to cool produce quickly to avoid damage.

Why Hydrocooling?

While there are a number of other cooling methods for fruits and vegetables, hydrocooling is one of the fastest ways to preserve fresh produce. It reduces the time that produce is exposed to damaging natural elements and speeds up the harvesting process as it allows large amounts of produce to be cooled at once. There are a variety of hydrocooling methods, but the most commonly used is the conventional method in which harvested produce travels along a conveyor belt under a shower of chilled water.

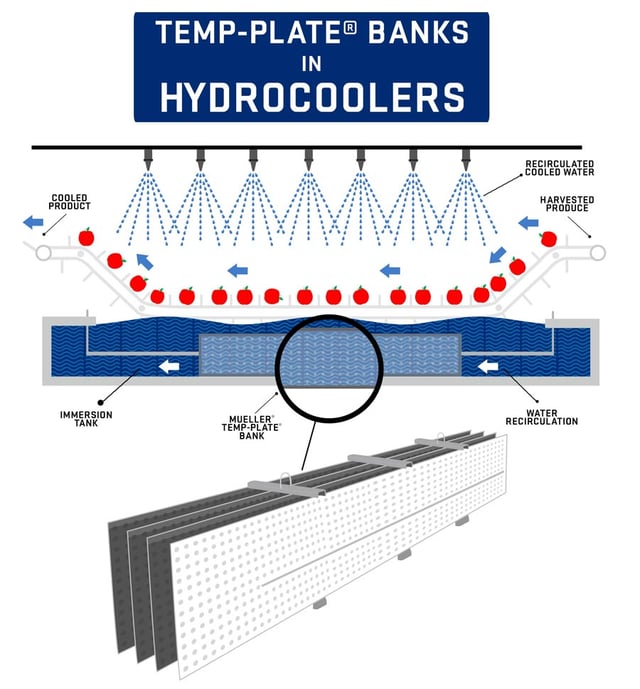

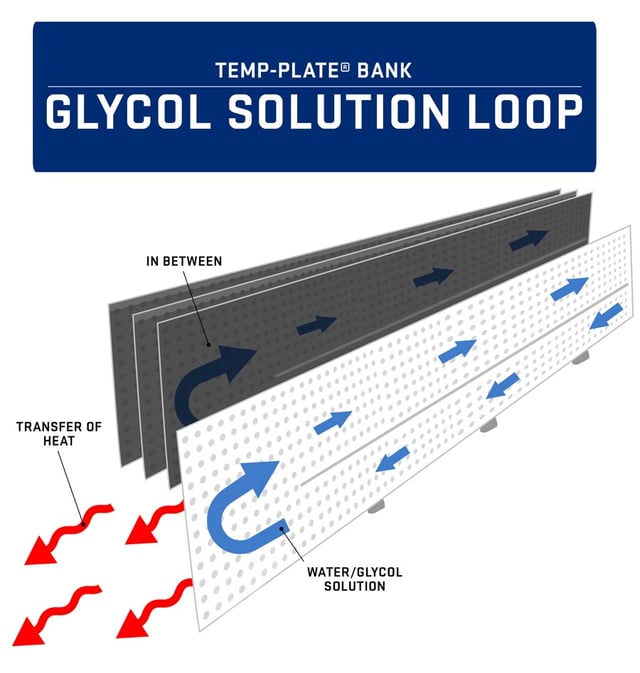

Use of Immersed Temp-Plate® Banks in Hydrocooling

Within the last five years, the use of immersed Paul Mueller Company Temp-Plate® banks in hydrocoolers has increased significantly. The immersed Temp-Plate® banks provide an energy-efficient heat exchanging solution for rapidly chilling and recirculating the water for hydrocooling. With conventional cooling methods, the water cannot be recirculated as the debris from the produce has to be cleaned out each time. However, by utilizing immersed Temp-Plate® banks in hydrocoolers, this can be avoided as the strategic spaces between the plates prevent debris, from produce, from getting trapped. This allows the cooled water to recirculate repeatedly without the need for a filter and makes cleaning and maintenance quick and efficient as the plates are easily removable.

Benefits of Hydrocooling with Immersed Temp-Plate® Banks

Overall, utilizing a hydrocooler that is equipped with immersed Temp-Plate® banks is one of the quickest and most efficient ways to cool large capacities of fresh produce. This provides significant savings in energy costs and time spent maintaining the system and reduces waste caused by harvested produce getting damaged.

If you are interested in equipping your hydrocooling system with immersed Paul Mueller Company Temp-Plate® banks, contact us for a consultation with one of our heat transfer experts.