It's just one little number out of many that you have to calculate when designing a stirred tank mixer application, but it is probably more important than you realize. It impacts almost every part of your product, equipment, and process.

What is the Reynolds Number?

Technically speaking, the Reynolds number is a dimensionless number representing the ratio of dynamic to inertial viscosity (or as NASA put it, the ratio of inertial force to viscous force) for liquids in parallel planes under shear.

But what does that mean in layman's terms? The Reynolds number is a measure of how easily liquids flow versus how much they resist flow under shear. Liquids with a low Reynolds number have a high viscosity, and liquids with a high Reynolds number have a low viscosity.

History of the Reynolds Number

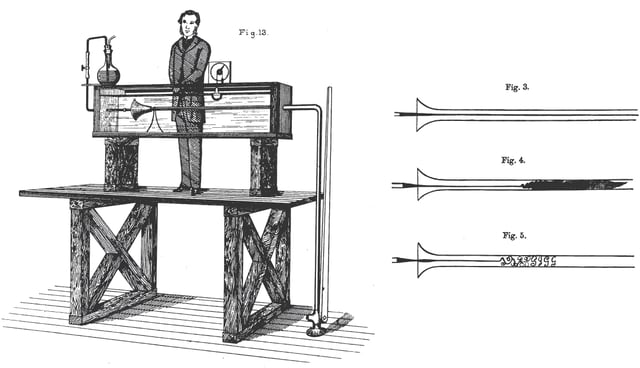

The Reynolds number is named after Osborne Reynolds, a British physicist and engineer. In 1883, he popularized the use of the Reynolds number after performing a visually compelling experiment about fluid turbulence. He used water tank and a glass pipe with a valve on the end to create a steady flow of water. Then, he placed a small tube with a colored dye flowing directly into the end of the pipe and the top of the stream. When the water flowed slowly, the dye followed a defined line nearly to the end of the pipe. As he increased the flow rate, the dye began to break up nearer and nearer to the beginning of the pipe.

Describing Viscosity Using the Reynolds Number

Reynolds numbers are often divided into three distinct groups that provide more description of a liquid's behavior.

While each mixture will require a different level of mixing, these general categories hold true. Some tank mixing applications utilize this Reynolds number framework:

- Laminar region: Re < 100

- Transition region: 100 < Re < 10,000

- Turbulent region: Re > 10,000

In other words, the Reynolds number helps you determine whether or not adequate mixing will take place at a certain set of equipment specifications such as impeller diameter, horsepower, torque, and many others.

Because mixing primarily happens where fluids are turbulent, it's important to factor in the Reynolds number for specific compounds and ingredients used in your application.

Does the Reynolds Number Affect Equipment Selection?

The Reynolds number plays a critical role in impeller sizing and design, which helps you achieve the desired agitation level. Most impellers are designed for transitional and turbulent Reynolds numbers, but there are also impellers designed for laminar applications.

Using an incorrect impeller for the Reynolds number at various stages of mixing and ingredient additions can greatly reduce the efficiency of your impeller.

The Reynolds number will also factor into the amount of time it takes to complete the mixing process. If a liquid is resistant to flow, then it will take longer to mix. If the liquid flows easily, then it is likely that the time it takes to achieve your desired results will be less than what could be expected from laminar applications.

Along those same lines, you will need less horsepower and torque to mix materials with high viscosity. Select a motor with the right amount of horsepower for your application so that you don't pay more than you need to and so that you don't wind up with an inadequate mixer. Selecting the right equipment will save you both time and money.

There are many more ways that the Reynolds number impacts mixing; from the product materials to the gearbox, it's part of every step along the way to a successful final result. Most mixer suppliers will help you with make calculations that use the Reynolds number as well as help you determine the right mixer for your application.