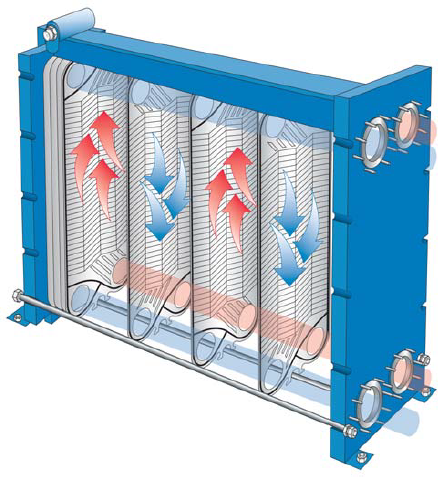

Plate heat exchangers are a highly useful industrial component for passively (without extra energy) controlling fluid temperatures using other fluids that may already be part of the industrial process. Here’s a brief explanation of how they work and their benefits, as well as links to more helpful resources.

Construction

Plate heat exchangers are constructed with a series of plates held together in a large frame. As you can see above, there are two inputs and two outputs, and the spaces between plates alternate between the two liquids. The large amount of surface area, as well as the metal’s corrugation contribute to much greater heat transfer than a traditional shell and tube heat exchanger of similar size. This is a well-known advantage of this technology.

Figure 1 - Exploded view of a plate heat exchanger

Materials

Depending on the types of heat exchangers used and the fluids being put through the exchanger, some materials may be better than others. For example, if you’re using seawater to cool reactor exhaust, the salt content of the brine may corrode conventional stainless steel. For an application like this, you’ll need to look into titanium plates. The same logic applies to any particularly corrosive chemical, usually some kind of chloride compound.

Modularity and Maintenance

Plate heat exchangers are fairly easy to disassemble and reassemble, thanks to their design. One benefit of this is modularity. If you expand your process, you don’t have to buy a new heat exchanger, simply add more plates to the one you already have. Another benefit is ease of maintenance. If your plates get fouled up, you can take it apart and clean them by hand. Or, if you have a water pump and the right chemicals, you can clean it the same way as you would a shell and tube heat exchanger.

Gasketed, Brazed or Welded?

Most plate heat exchanger manufacturers have three different ways to seal the plates together: gaskets, brazing or welding. The latter two options take away the modularity, but they add stability and reliability. That low-maintenance factor is one reason brazed plate heat exchangers are preferred in the HVAC industry, where small units are installed in combi boilers or similar heating equipment. However, gaskets are preferred in most industrial processes to allow for easier maintenance and possible expansion.

Heat transfer technology will be instrumental in developing more sustainable processes. A perfect example is the Alaska Sealife Center used plate heat exchangers to  deep within the Alaskan Ocean. They used that heat to nearly eliminate their utility usage to heat the entire facility.

deep within the Alaskan Ocean. They used that heat to nearly eliminate their utility usage to heat the entire facility.

More Resources

If you’re reading this article because you’re not sure if a plate heat exchanger is the right solution for you, here’s a link to post on The Differences Between Different Types of Heat Exchangers.

Lastly, if you liked this article or found it helpful, please leave feedback or questions on social media.